Hot Stamp & Heat Transfer

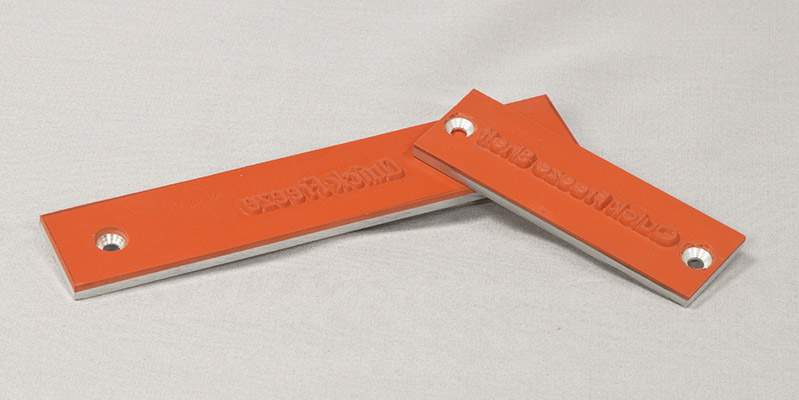

Hot stamping is a decoration technique that has been around for decades. This technique doesn’t involve wet inks or solvents, but rather a heated die and a “foil” strip carrying the ink that is to be transferred to the part. There is no cure time required and the parts can be handled and packaged immediately after being decorated. The hot stamping process is simple - by applying heat and pressure through the foil, the image or text on the die is transferred to the part. Hot stamping can create decorations on your custom injection molded plastic parts that are both detailed and durable and is compatible with all thermoplastic materials.

Hot stamping taken to the next level.

Heat transfer is a decoration process that is very similar to Hot Stamping. This process has the same benefit of being a dry process with no solvents or liquid inks to mix. Heat Transfer takes the Hot Stamping process to a higher level and introduces the ability to decorate your injection molded plastic parts with multi-colored graphics in a single pass. The heat transfer image is pre-printed on a web of plastic that carries the image to the part. With continued advances in machine controls, the ability to precisely position the image on your plastic part has never been better. Let a Wabash Engineer evaluate your Heat Transfer application today.

Product Inspirations

- Appliance Controls

- Knobs

- Control Panels

- Consumer Goods

- Button Labels