2K, Two-shot, and Overmolding

Join Two Materials In One Mold

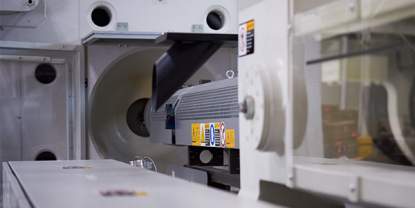

2K, two-shot, multi-shot, and overmolding are all names for similar processes. Traditionally, overmolding involved taking a part molded in one tool / machine and placing it inside a second tool to have the second material molded over the original part. The result is a part that has a robust bond between the two materials. Modern overmolding is now referred to as 2K or two-shot. This process eliminates the intermediate step of packaging, transporting, and manually loading into a second tool.

Through the use of automation and innovations in machine and tool design, we are able to provide a two-shot part in the same amount of time it previously took to mold only the substrate. This happens using only one tool and one injection molding machine that is equipped with multiple injection units. The savings is significant and allows us to deliver a high quality part that serves our customers' needs at a fraction of the cost compared to the multiple step process used in the past. Let us help you redesign your two component assembly to take advantage of this technology and reduce your costs.

Product Inspirations

- Vibration Reduction

- Sealing Applications

- Elastomeric Materials

- Appliance Decorative / Functional

- Anti-Skid