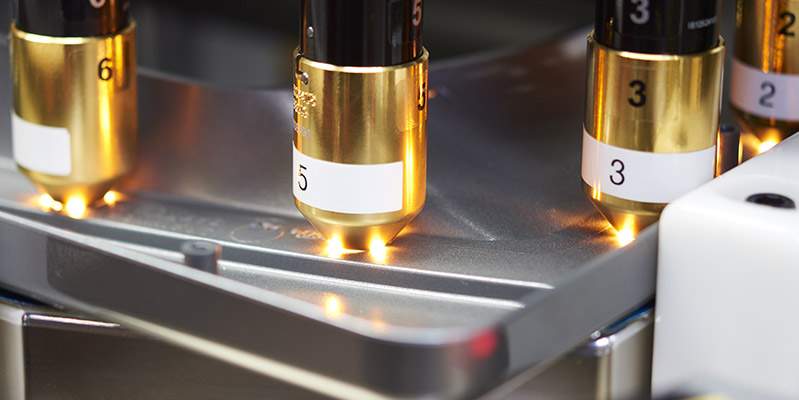

IR Infrared Welding

Non-contact heating offers clean & consistent welds for your injection molded parts.

This welding process involves heating the weld areas through the use of non-contact infrared heaters. Once heated to an appropriate temperature, the part are then joined together. The IR welding process allows the plastic weld areas to be heated without having to contact the part. This enables parts with small or delicate weld areas to be welded without unnecessarily distorting the material prior to welding. The end result is a more consistent and reliable weld. Contact Wabash today to bring your IR / infrared welding project to reality.

Product Inspirations

- Appliance Doors

- Automotive Assemblies